Introduction and Industry Context

The seafood processing industry operates in a highly time-sensitive and compliance-driven environment, handling fresh, frozen, and value-added seafood products for domestic and export markets. Processors must manage procurement from fishermen and suppliers, cold storage operations, grading, processing, packing, traceability, quality control, and strict regulatory compliance while maintaining product freshness and yield.

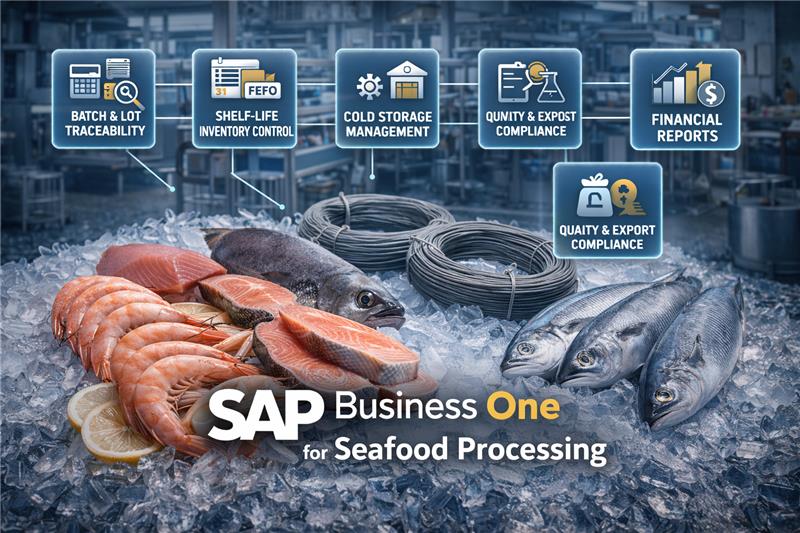

Many seafood processors rely on disconnected systems for procurement, production, cold storage, sales, and finance, leading to limited batch visibility, wastage due to spoilage, manual compliance reporting, and delayed decision-making. SAP Business One provides a unified ERP platform that integrates procurement, production, inventory, quality, traceability, finance, and compliance—delivering real-time visibility and operational control across the entire seafood processing lifecycle.

Key Challenges

- Perishable Inventory & Shelf-Life Management

- Batch & Lot Traceability for Compliance and Exports

- Yield Losses During Cleaning, Processing & Freezing

- Cold Storage & Temperature-Sensitive Inventory Control

- Manual Quality & Regulatory Documentation

- Limited Visibility into Product-Wise Profitability

Our Solutions

- End-to-End Batch & Lot Traceability

- Shelf-Life, Expiry & FEFO Inventory Control

- Yield, Wastage & By-Product Management

- Integrated Cold Storage & Warehouse Management

- Quality Control & Export Compliance Documentation

- Integrated Finance & Profitability Analysis

- End-to-End Batch & Lot Traceability

Implementation Approach

- Discovery: Workshops with procurement, production, quality, cold storage, sales, and finance teams to understand processing workflows, compliance requirements, traceability needs, and reporting expectations.

- Configuration:nSAP Business One configured for batch-controlled inventory, yield tracking, shelf-life management, quality workflows, and financial controls specific to seafood processing.

- Integration: Integration with weighing scales, barcode/RFID systems, cold storage monitoring systems, and export documentation platforms where required.

- Training & Support: Role-based training for plant operations, quality teams, warehouse staff, and finance users, supported by post go-live assistance and continuous optimization.

Results & Business Impact

| Area | Business Impact |

|---|---|

| Traceability & Compliance | Faster, audit-ready export and regulatory reporting |

| Inventory Control | Reduced spoilage and better shelf-life management |

| Yield Optimization | Improved recovery and reduced processing losses |

| Cold Storage Visibility | Better control over temperature-sensitive stock |

| Profitability Insights | Accurate product and batch-wise margin tracking |

The unified ERP platform improved coordination across procurement, processing, cold storage, quality, and finance teams—enabling better compliance, reduced wastage, and data-driven decision-making..

Why Clockwork Business Solutions?

Clockwork Business Solutions brings strong expertise in delivering SAP Business One solutions for food processing and export-oriented industries, including seafood processing.

Key strengths include:

- Industry-specific SAP Business One configurations

- Expertise in batch, yield, and cold storage management

- Seamless integration with plant and warehouse systems

- Proven implementation methodology and long-term support

Conclusion

By implementing SAP Business One, seafood processors gain a centralized platform to manage procurement, processing, cold storage, quality, sales, finance, and compliance with complete visibility and control. This integrated approach improves operational efficiency, ensures regulatory compliance, reduces spoilage, and supports sustainable growth in a highly competitive seafood market.